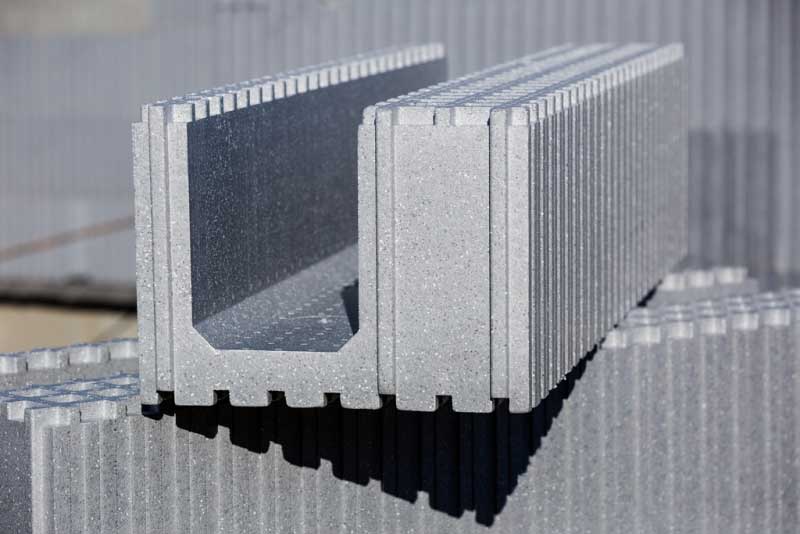

What are ICF systems?

ICF = insulated concrete forms.

Insulating blocks or Duplo for adults for DIY under the guidance of a technician.

1951: Production of polystyrene foam (EPS®) at BASF.

1965: The Austrian styrofoam pioneer Herbert Fitzek produces the common wood concrete shuttering block commonly found there out of polystyrene foam.

According to Wikipedia, the first patent for it (1966) was registered by Canadian Werner Gregorie.

You can find the link here.

https://en.wikipedia.org/wiki/Insulating_concrete_form

In the 90s, it was still very easy to build these houses yourself. (25 block) Today it is becoming more difficult due to European energy regulations.

What actually is an ICF system?

Formwork elements made of polystyrene / Neopor®

Very simply put, blocks to be put together and filled with concrete.

Suitable for all walls which depend on thermal insulation and cooling. From single family homes to high-rise buildings. But even refrigerated warehouses for hotels and abattoirs etc. can be easily built in such a way that the thickness of the insulation comes inside.

U values (thermal transmittance values, formerly k-values):

In Europe, there are various strengths from different manufacturers.

Here are the most common measurements:

25 interior wall ca. 0.27 W/(m2K)

30 and 31 exterior walls ca. 0.17 W /(m2K)

35, 37 and 40 exterior walls ca. 0.13 W /(m2K)

43 and 45 exterior walls ca. 0.10 W /(m2K)

“Energy-saving and environmental protection world champion in modules for solid-walls”.

40-45 wall suitable for “passive houses” = houses without a traditional heating system!

Perfect and sophisticated complete programme:

Elements with rigid foam plastic or a wire web Standard delivery widths in Europe are currently 25-45cm wall thicknesses. Thermal bridging elements for lintel, ceiling finish, roller shutter boxes, bay windows, round corners, arches, overhangs, etc. are available depending on the manufacturer. There is also a staircase, ceiling, and roof insulation programme to go with them.

Ideal for amateur builders with family, friends, and technical assistance.